BASED IN BIRKENHEAD SINCE 1973

BASED IN BIRKENHEAD SINCE 1973About Us

At Hamilton Engineering, our team is our greatest asset.

Since 1973, we’ve been passionate about developing local talent. Our apprenticeship program isn’t just about training; it’s about nurturing the next generation of metalworking professionals.

We partner with local engineering colleges to provide comprehensive training, ensuring that skills are both traditional and cutting-edge.

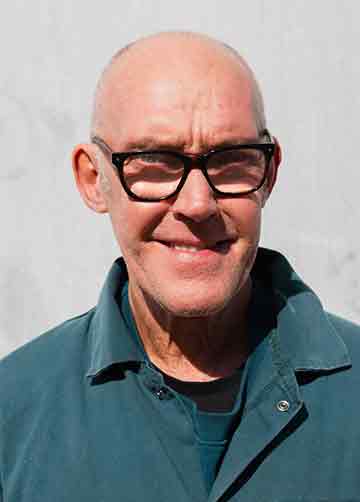

John Hamilton

Managing Director

We are committed to nurturing talent from within. Many of our senior team members started their journeys as apprentices, highlighting our dedication to professional development and internal growth progression.

By investing in local talent, we’re not just building metal structures; we’re creating careers, supporting families, and contributing to the regional economy’s strength.

We value:

PRECISION

CUSTOMER SATISFACTION

TEAMWORK

INNOVATION

Continuous Improvement

QUALITY

Our Team

Meet Our Talented Engineers

Career Development

A Commitment to Craftsmanship across the team

Master Welders

Sheet Metal Specialists

Fabrication Experts

Design Technicians

Apprentices

Certifications & Qualifications:

Our Team’s Collective Strengths:

- 200+ Years of Combined Experience

- Diverse Skill Sets

- Commitment to Craftsmanship

- Continuous Learning Culture

- Intergenerational Knowledge Transfer

Career Opportunties

Are you interested in a career that combines traditional craftsmanship with modern innovation? Explore our current opportunities and start your career as part of the local legacy of shaping metal for the last half a century.